Solutions that make underground and surface mining operations more profitable.

Your mining operation relies heavily on conveyor belts to transport the material taken out of the ground and get it into production, so the durability and efficiency of your equipment is critical. Unscheduled downtime is unacceptable, and fugitive material is not only a maintenance and cleanliness issue – it represents lost profit.

Whether you’re mining coal, precious metals, base metals or aggregates, you can rely on the fact that Martin Engineering has been a leader in the original development of the conveyor belt equipment used today to make mining operations cleaner, safer and more productive.

When you’re surface mining or mining underground for hard or soft rock, your challenges are formidable and you could definitely benefit from our experience with mining operations that literally spans the globe. We employ many people who have worked extensively in the mining industry, so we’re able to apply lessons learned from all over the world to solving your everyday problems.

Effective solutions to your most challenging problems.

Effective solutions to your most challenging problems.

We can help you better address the dust suppression issues associated with surface mining and keeping good community relationships. We can help you deal with the belt cleaning challenges associated with the large amounts of water used in your underground mine. We share your concerns for your employees when it comes to respirable dust and other health and safety risks inherent in the mining industry.

Martin manufactures conveyor equipment designed to keep your product moving efficiently from the face of an underground coal mine or the high wall of a quarry, through the prep plant, to the boiler or loading site. With our quality products and our skilled team of installation and maintenance personnel, we help you keep your conveyor belt operation running cleanly and safely at max capacity.

Knowledgeable people. Unmatched service.

Our customers know that Martin provides an unmatched level of support and service. We take the time to understand the specifics of your mining operation, which allows us to provide the correct equipment for your problem and point out areas where you can be even more productive, more efficient and more profitable.

With our experienced technicians, we’re able to offer an unmatched level of support and service to the facilities we visit. And many of our engineers and technicians have previously worked for mining companies like yours, so we have a unique perspective and advantage when it comes to knowing the issues you face from your viewpoint. We have decades of direct experience, and we know where the process can get bogged down. More importantly, we know how to fix the problems when they arise.

Contact a Martin representative to find out how we can apply our vast mining experience and put our superior conveyor belt products to work solving your problems today!

- Move material more efficiently along conveyor belt systems and minimize carryback

- Keep downtime for maintenance and belt cleaning to a minimum

- Reduce spillage and equipment damage by keeping conveyor belts aligned

- Manage airborne dust and minimize the risk of explosion and inhalation

- Eliminate the need for workers to enter confined spaces

- Prevent material from spilling off of moving conveyor belts

- Deliver more product by maximizing your mine’s overall throughput

- Reduce costs by minimizing waste and reducing energy consumption

- Eliminate excessive downtime for maintenance and housekeeping

Client Tests Martin Belt Cleaners In Side-By-Side Comparison

Belt Cleaner Improves Efficiency And Extends Blade Life

Copper Mine Solicits Martin's Expertise For Conveyor Belt Improvements

Air Cannons Prevent Buildup on Kiln Walls

Air Cannons Immediately Increase Production

Martin Engineering Offers Dependable Solutions When Others Fail

Chute Structure Products Reduce Unscheduled Downtime

Martin Transfer Point Solution Saves Mainframe

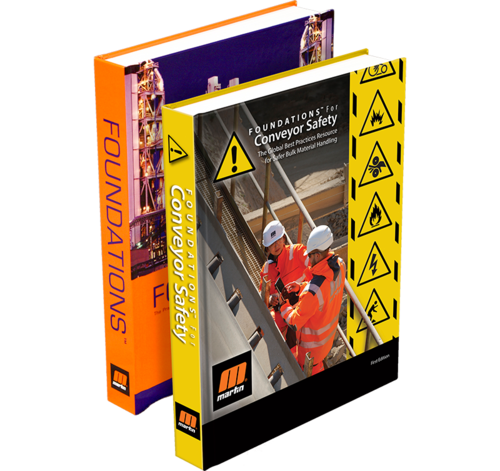

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Train Your Personnel For Better Belt Conveyor Performance and Safety

Foundations™ Training workshops train your plant operating and maintenance personnel and engineers about belt conveyors – how they work and how to make them work better. From a Basic Introduction to belt conveyors and safety to an Advanced Training option for your skilled and experienced members, Martin will share our 70 years of experience and research with your team members. You can't afford not to educate your team with Martin!

Ask About Our On-Site and Online Options