When the flow of material gets stuck, shake it loose!

For many years, the necessity to store material in bulk has created a problem - how to get it out of the storage vessel. Typical problems include bridging, ratholing, clinging and arching. Once a pluggage exists, it becomes necessary to remove it in order to continue with production. One of the first things an operator will do is try to dislodge it in some manner. Historically, techniques such as water and air lances, silo cleanout equipment, shot gun blasts and even dynamite have been used to eliminate material blockage. The most common means of material removal over the years is the use of a sledgehammer.

For many years, the necessity to store material in bulk has created a problem - how to get it out of the storage vessel. Typical problems include bridging, ratholing, clinging and arching. Once a pluggage exists, it becomes necessary to remove it in order to continue with production. One of the first things an operator will do is try to dislodge it in some manner. Historically, techniques such as water and air lances, silo cleanout equipment, shot gun blasts and even dynamite have been used to eliminate material blockage. The most common means of material removal over the years is the use of a sledgehammer.

Having lived with these storage flow problems for decades, new techniques were developed to reduce these occurrences and address storage flow problems before a blockage occurs. One safe and efficient solution is the industrial vibrator, invented by Edwin F. Peterson in 1944, and the start of Martin Engineering.

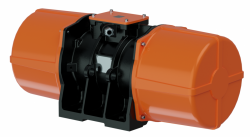

Martin Engineering manufactures vibrators to prevent bin and hopper flow problems as well as rotary electric vibratory drives for industrial processing equipment.

The application of vibratory drives to processing equipment has found acceptance throughout industries world wide, primarily in increasing production throughput and reducing operational costs. The most typical applications include conveying or feeding, screening, draining, dewatering, product sizing, compaction, testing of components, as well as bin, hopper and chute evacuation.

Industry Applications For Vibration Solutions:

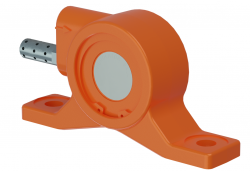

Derrick® Screen Vibrator Replacements

The Martin® Screen Vibrator is designed for vibrating screens and serves as a direct replacement for Derrick® Screen Vibrators. Our vibrators are guaranteed to fit perfectly on your Derrick® Screens. We'll even BEAT THEIR PRICES and you can have them SHIPPED THE SAME DAY!

Derrick® is a registered trademark of Derrick Corporation, Buffalo, New York. There is no affiliation between Derrick Corporation and Martin Engineering.