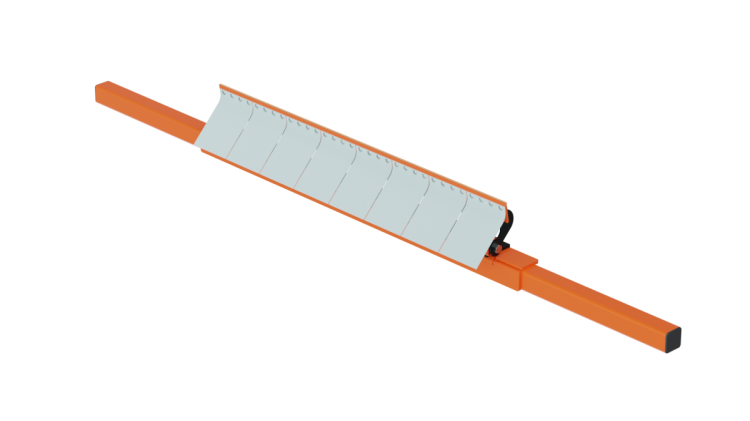

SQC2S™ Orion Secondary

The SQC2S™ Orion Secondary Belt Cleaner is the most versatile and best selling secondary cleaner, making it a reliable solution for a broad range of demanding applications. Its rugged construction withstands harsh environments, high-speed belts, and high-tonnage loads. The SQC2S™ Cleaner is designed for medium- and heavy-duty applications on belt widths from 18 to 96 inches (~400 to 2400 mm) operating at speeds up to 1500 fpm (7.5 m/sec).

The SQC2S™ Orion Secondary Tensioners allow simple alteration of blade-to-belt pressure to maintain cleaning efficiency regardless of blade wear. A lock pin keeps the tensioner in place to maintain constant tension while the blades conform to the belt profile by adjusting individually to provide continuous contact across the belt. Its compact design allows installation in close quarters while its narrow profile resists material buildup.

Blade replacement is simple and straightforward; remove the pin, slide the cartridge out, service, and return to duty. Available with acid-resistant blades for belts with clips and suitable for use with reversing belts. Farside Tension Adjuster is also available to simplify service, allowing adjustments to blade tension to be made from a single side of the belt.

The SQC2S™ Orion Secondary offers five unique blade cartridge options to match the needs of your application.

SQC2S™ Orion Blades

Utilize a unique flexing blade mount to cushion splice impact while maintaining cleaning pressure. The blade’s “paint-scraper" cleaning angle provides maximum removal of stubborn carryback while the blade holder flexes to allow the blade tip to deflect in the direction of belt travel for splice passage. Tungsten carbide blade tips featuring individually machined blade adjustment provide effective and long-lasting cleaning while the unique blade shield allows removed material to slide off without buildup.

Product Specifications

| Belt Width | Up to 96 in (up to 2400 mm) |

| Belt Speed | Up to 1500 fpm (up to 7.5 m/s) |

| Temperature | Between -30 degrees F and 300 degrees F |

| Corrosive Conditions | Yes |

| Underground Applications | Yes |

| Accommodates Mechanical Splices | Yes |