Case Studies

XHV Air Cannons

Each unit is activated with a new type of 110-volt, negative-firing solenoid. Installers also devised a mechanism by which the discharge volume from the bin determines the firing sequence for the system. Since installation in February of 2014, the company has not reported a single instance of ratholing in the hopper, and no need for clearing an obstruction.

Read MoreTyphoon Air Cannons at Zinc Mine

The firm was experiencing blockage issues in the lime bin at both discharge points, which impacted the pH of the lime and caused material deterioration. Electric vibrators on the bin were ineffective and prone to failure, requiring plant personnel to manually clear the accumulation. The situation was wasting valuable manpower and affecting overall efficiency. After a thorough review of the process, Martin Engineering technicians recommended a series of air cannons to better control material flow and minimize buildup. Since the installation, operators report experiencing no material buildup or blockage issues, as well as improved quality from the stabilized pH of the outflow.

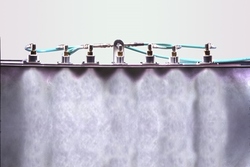

Read MorePSP 1333 - Skirtboard Covers

The pitched cover design alleviates environmental problems caused by fugitive dust emissions by ‘shedding’ debris and material in the settling zone.

Read MoreMartin® Tracker HD solves belt misalignment issues

The conveyor feeding the crushing unit at Argonaut Gold's Minera Pitalla was experiencing serious belt alignment issues. The mistracking belt was rubbing against the return roller frame, causing damage to both the belt and the frame.

Read MorePSP 1330 - Truck Vibration

A Midwest dump truck, trailer and truck body manufacturer needed a high-quality and reliable vibration solution for their products intended to haul the heaviest and tackiest cargo.

Read MorePSP 1328 - Transfer Point Solutions

One of the largest silver producers in North America was experiencing excessive dust and spillage on the conveyor leading from the crusher to the surge pile, which lowered air quality, required 5-10 man-hours per day to clean, and caused unscheduled downtime from premature equipment failure.

Read MorePSP 1327 - Belt Cleaners in Gold Mining

They realized that the equipment was no longer able to handle the overburden, and fugitive material was causing expensive equipment failures, unscheduled downtime and increased maintenance time.

Read MoreCleanscrape® Cleaner - Cement Plant

Operators found that polyurethane cleaner blades were unable to completely clean the belt. “The fines and mud take on the tacky consistency of toothpaste, causing it to cling to the belt along with smaller pieces of aggregate and shale.”

Read MoreAir Cannon - Fertilizer Plant

A fertilizer production plant using a cage mill crusher was experiencing excessive downtime from the buildup of fine phosphate-based fertilizer on the walls of the enclosed unit.

Read MoreMartin® Tracker HD

Unscheduled shutdowns were necessary at least once a week to realign the belt manually and remove the fugitive material.

Read MoreMartin® Silo Cleaning and Air Cannons Prevent Limestone from Clogging and Shutting Down the Silo

A Drake Cement facility north of Paulden, AZ was experiencing clogging issues on a weekly basis, forcing maintenance personnel to spend up to 10 hours to clear the blockage using tools and compressed air.

Read MoreCleanScrape® Cleaner Reduces Need for Cleanup

A U.S. rock quarry was experiencing carryback on one of its conveyors. Material adhered to the return side of the belt, collected around the mainframe and gummed up the rollers, requiring downtime for maintenance.

Read MoreSpillage Was Creating Wasted Labor and Material Loss

With proper belt support, the load is stabilized and material is contained throughout the transfer point.

Read MoreSevere Belt Mistracking in the Loading Zone Decreased Safety and Increased Downtime

After installing tracking systems, the belt is centered and there has been no downtime due to misalignment.

Read MoreThe World's Largest Producer of Talc Improves Safety and Reduces Cleanup Costs with Belt Cleaners

Inadequate belt cleaning allowed for pasty material to remain on the belt and spread across the floor, creating an unsafe work atmosphere.

Read MoreCleanScrape® Cleaner Improves Operations At Coal-Fired Power Plant

A coal-fired power plant was experiencing massive amounts of carryback on the belt conveyor, which runs 24/7. Bottom ash and water requiring constant cleanup, and the wet, abrasive material caused premature component wear and presented a potential hazard of slips and falls. Standard belt cleaners lasted only days, and ceramic-reinforced models delivered just two weeks' service.

Read MoreQC1™ Cleaner HD STS Clears Belt of Adhered Carryback for Metal Recycler

A recycler of residuals from the production of iron and steel was experiencing extreme carryback on a main material transport belt, which was causing unsustainable plant pollution. An existing cleaner made from a horizontal metal plate tilted slightly to face the discharge chute did not adequately remove dust and fines from the cracks and divots in the belt.

Read MoreAir Cannons Stop Sand From Clogging in Dual-Spout Pyramid Hopper

Aggregate Industries was experiencing clogging sand in its dual-spout pyramid hopper. Vibrators were used to loosen material, but vibrating metal walls turned the hopper into a giant horn, which caused a loud, unpleasant sound throughout the work area.

Read MoreCleanScrape® Cleaner Eliminates Extensive Carryback On Conveyors Carrying Slag

A cement plant located in Western Ukraine was experiencing extensive carryback on conveyors carrying slag. Fugitive material built up on floors and encapsulated rolling components, causing excessive downtime for maintenance and cleaning. Increased operational costs for labor and replacement parts inspired managers to seek alternatives.

Read MoreCleanScrape® Cleaner Eliminates Excessive Carryback on Conveyor Carrying Wood Chips

A producer of Medium Density Fiberboard and Chipboard was experiencing excessive carryback on the conveyor system transporting wood chips to the screening process. During this process the wood is damp and sticky, causing smaller particles to cling to the return side of the belt. This required extra labor to clean the area 2 hours per day, raising operating costs and affecting workplace safety.

Read MoreMartin Belt Cleaners Eliminate Carryback

Siam City Cement in Saraburi, Thailand was having trouble with excessive carryback and spillage along the length of their conveyor path. This posed a potential workplace hazard and required workers to be assigned for regular cleanup. Rolling components also needed frequent replacement, which led to expensive downtime and increased the cost of operation.

Read MoreMartin Provides Complete Overhaul of Transfer System to Handle the Impact of Limestone

The Martin Marietta Hunter Cement Plant experienced equipment breakage, belt damage and spillage issues on the B-06 conveyor leading from the limestone storage dome to the facility. The previous equipment was inadequate to handle the impact of limestone. Idlers cracked and cargo would not center sufficiently, causing excessive spillage around the transfer area and along the belt path, leading to long periods of downtime.

Read MoreAir Cannons Stop Transfer Chute Clogging and Conveyor Belt Backups

The Hunter Cement Plant facility in New Braunfels, Texas was experiencing transfer chute clogging and conveyor belt backups from wet fines and aggregate on its partially-covered D-07 conveyor. Heavy seasonal rain caused serious spillage issues and accumulation in the chute, which halted plant production.

Read MoreChute Clogging And Spillage Corrected With CleanScrape® Cleaner

A coal-fired power plant was having chute clogging and spillage issues. The existing primary and secondary cleaners allowed uneven discharge of material, which clung to chute walls and caused clogging, requiring periodic downtime for adjustment. The blade edges wore quickly, causing enough carryback and spillage to encapsulate the cleaners.

Read MoreFailing Rubber Seals Replaced With Martin® ApronSeal™ Skirting

A coal-fired power plant was experiencing failures of the rubber/fabric seals at the top of the chute wall on its Train Unload Vibratory Feeder. Unable to handle the powerful vibration, the thin rubber seals allowed dust and fines to spill from the chute. Workers had to clean up at least once per month, and the spillage created a potential workplace hazard.

Read MoreSecondary Belt Cleaner Eliminates Need For Manual Scraping And Washing

A small power plant burns sugarcane bagasse that would otherwise be waste material from processing. The hot gas generator produces hot ash, which must be cooled with moisture and transported by conveyor. The moist ash is very difficult to remove from the conveyor, forcing operators to run a hose behind the existing scraper to wash the belt, wasting water and creating a mess.

Read MoreReplacing Inadequate Equipment Improves Productivity

A coal mine was experiencing heavy spillage and system damage along the length of a main conveyor due to inadequate loading zone equipment. Impact idlers allowed excessive belt sag, causing high volumes of spillage. Dust and fines fouled idlers, and rocks got lodged between the belt and the skirt, resulting in unscheduled downtime due to frequent equipment failures and chute liner replacements.

Read MoreJohannesburg, Gauteng, South Africa

A manufacturer of powdered washing detergents in South African was experiencing problems with carryback on one of its main conveyor belts. Small particles with a high moisture content clung to the belt and migrated to the rolling components of idlers and pulleys, resulting in equipment failures and mistracking. This caused excessive wear on the belt and shortened its life considerably.

Read MoreMartin® Belt Cleaners Minimize Downtime For Cleanup

PT Antam Mining of Indonesia had inadequate belt cleaners causing belt damage, spillage and carryback on a reversing belt within the mine. The previous equipment did not keep a seal across the belt profile. Incomplete cleaning caused excessive carryback and spillage along the return belt path, increasing the need for cleanup.

Read MoreMartin Transfer Point Solution Saves Mainframe

A nickel mining plant was experiencing excessive equipment wear and damage at a main transfer point leading from the rotary dryer, handling 71,430 tons per month of bulk material. The impact force of cargo on an unsupported belt was cracking idlers and bending the mainframe. The damage forced operators to shut down the entire system regularly to repair mainframe damage and replace broken equipment.

Read MoreMartin Provides Effective Belt Support Solution

A coal-fired plant handling large quantities of synthetic gypsum was experiencing fugitive material problems, with dust and spillage piling up and large chunks of gypsum falling off the belt. Martin technicians determined that inadequate belt support was the primary cause of the problem, allowing material to escape from the transfer point’s loading zone.

Read MoreNew Belt Cleaner Saves 24 Hours Per Week In Cleanup Time

An aggregate facility handles 1.5 million tons of limestone per year. After experiencing excessive carryback on their existing conveyors, they wanted to make sure to address the issue when adding a new conveyor. The plant spent 16 to 24 hours per week cleaning up. There was also excessive damage to the conveyors.

Read MoreCleanScrape® Cleaner Improves Operations At Rock Quarry

A rock quarry was experiencing carryback on one of its conveyors. Leading from the quarry to the interior of the facility, the outdoor portion of the belt was exposed to extreme weather, even though it is covered. Material adhered to the return side of the belt, collected around the mainframe and gummed up rollers, requiring downtime for maintenance and raising the cost of operation.

Read MoreChute Structure Products Reduce Unscheduled Downtime

An iron ore mine was experiencing premature deterioration on the wear plate of a transfer chute, leading to perforation and spillage. Every 60 days, operations would be interrupted while workers performed a potentially dangerous chute entry to cut out the material and replace it. Labor for cleanup, unscheduled downtime and expensive replacement equipment made the situation unsustainable.

Read MoreMartin Saves Cement Plant $5,000 Per Month In Labor And Equipment

A plant was experiencing major problems with dust and material spillage on their crusher discharge belt coming from the quarry. This required clean up a minimum of once every week. It was also causing premature failure and belt wear due to idlers freezing up. The plant estimated this problem was costing $5,000 per month in labor and equipment costs.

Read MoreBelt Misalignment Causing Structural and Belt Damage

A conveyor belt at a coal mine became loose, ran askew and material was adhering to the corrective roller. This misalignment caused the belt edges to wear, reduced the life of the belt and increased spillage along the conveyor. These problems not only impacted the material handling efficiency but also increased the labor intensity, and created serious environmental pollution.

Read MoreRecycling Plant Experiencing Impact Damage And Belt Misalignment

Enertec is dedicated to the recycling of car batteries; they triturate and separate the plastic and the lead from the batteries, and then re-use it to manufacture new batteries. Their conveyor belt suffered from impact damage and misalignment. Some of the batteries ran down the back of the chute, which caused damage to the conveyor belt and also to the tail pulley.

Read MorePrimary And Secondary Belt Cleaners Reduce Excessive Spillage

A cement factory uses belt conveyors to transfer limestone and clay. The factory workers had to clean up the excessive spillage daily on the return belt. The labor intensity got very high when the spillage mixed with water on rainy days. The factory was replacing the blades frequently at a great expense as well as creating additional exiting safety hazards.

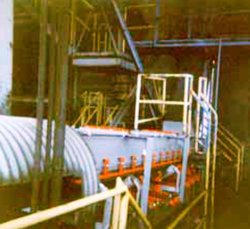

Read MoreAir Cannons Improve Material Flow While Optimizing Limited Space

Workers at a cement plant were experiencing some difficulties achieving their volume needed due to the preheater's spoon. The issue developed because the number of air cannons needed to keep the material flowing was limiting the physical space. The plant realized they needed to find a solution that would promote material flow while optimizing space.

Read MoreFoundations™ Operations & Maintenance Workshop Dramatically Improves Productivity

A cement plant in Colombia was experiencing severe spillage issues on several of its conveyors, causing belt misalignment and damage to the belt and rolling components. The situation increased maintenance costs, due to premature replacement of the belt and conveyor components, as well as the labor expense of three people for a full shift each.

Read MoreMartin Engineering Offers Dependable Solutions When Others Fail

A mine was experiencing dangerous spillage at the loading zone of its tower mounted conveyor. Despite installing equipment from a previous supplier, workers found that dust filled the tower and chunks of raw material spilled from the transfer chute onto the stairs, creating a potential workplace hazard. Twice a month operations had to be disrupted for 12 to 24 hours, so that a 4 to 5 person team could clean spillage.

Read MoreVPlow Stops Premature Wear And Misalignment Of Conveyor Belt

A cement manufacturing plant was experiencing fugitive material on the non-carrying side of the conveyor. The spillage would collect on the underside of the belt during its return run, and the material became trapped between the head pulley and the belt. The problem caused premature wear of the belt, as well as misalignment, and had the potential to damage the tail pulley, as well.

Read MoreBelt Support Products Solve Fugitive Dust And Spillage Problems

A coal plant had spillage and dust issues at two conveyor transfer points, because material was loaded onto the belts traveling 500 fpm with little control over impact or settling. The result was excessive fugitive dust throughout the facility. Inadequate chute control caused spillage to get caught between the belt and rubber tail pulley, damaging both.

Read MoreCement Plants Puts An End To Unscheduled Downtime With Martin Products

A cement plant was experiencing wear damage to the underside of the bucket on its excavator. Scooping slag and clinker off of a cement floor covered with a layer of crystalline residue, the bucket would scrape against the coarse material, degrading the metal and reducing the structural integrity. As a result, the 24-hour operation experienced regular unscheduled downtime.

Read MorePower Plant Challenged By Dust, Spillage And Carryback

A coal-fired power plant in India was facing serious problems from dust, spillage and carryback on one of its 60 conveyors, which handles 5,000 tons per hour of bulk material. The condition became so severe that the fugitive material was posing a safety hazard, requiring personnel to work in close proximity to the moving conveyor, creating another potential risk.

Read MoreTransfer Point Redesign Reduces Spillage And Dust

Handling 20,000 tons of crushed rock per month put the client at huge risk for material and profit loss. The plant estimated they were losing several thousands of dollars in labor expenses every week! Cleanup was not only an expensive maintenance task but also a dangerous one. Airborne dust can garner negative attention from regulatory agencies and lead to fines.

Read MorePaper Plant Having Trouble With Fugitive Material

The release of airborne dust can cause health concerns and create negative attention from regulatory agencies. Any material that spills off the conveyor is a loss - loss in material, profit and efficiency. The spillage also creates the need for manual cleanup which takes man-hours and is a dangerous task - putting workers in harm's way.

Read MoreMartin® Belt Cleaner Makes Replacing Worn Blades Easier

Conveyors were equipped with belt cleaners with segmented carbide blades. The belt cleaners have not performed well. The site has had problems with carryback under the conveyor rollers causing offsets and blockages. Additionally, maintenance and service on the belt cleaners was very difficult.

Read MoreSalt Buildup At Chemical Plant Causing Frequent Shutdowns

At the Arkema Group chemical site in France, a salt storage facility that stores and supplies salt had developed a lot of buildup from carryback along the belt. This buildup required a stop every six months for manual clean-up. After reviewing the system, Martin Engineering recommended two solutions.

Read MoreCement Plant Needed Transfer Point Solutions

Lafarge Cement was experiencing excessive spillage from one of its conveyor belts. The material was a mix of sand and water. Every time the extractor started, a mixture of sand and water discharges and the conveyor belt could not contain the material, in its current design. Martin Engineering was called to inspect the system and recommended a complete upgrade of the transfer points.

Read MoreAir Cannon Installation Results In 80% Fewer Stops For Cleanup

On the ship unloading conveyors at Arcelor Mittal in France, matter was accumulating along the belt and at the transfer points, which was reducing material flow. The client had to increase the number of stops to manually clean-up the material, generating fairly substantial additional costs.

Read MoreRepeat Client Hires Martin Engineering For Additional Product Installation

An aggregate plant needed a cleaning solution for its internal conveyors. Having already used the services and products from Martin Engineering in the past on other sites, they turned to Martin for help with this project. The solution recommended by Martin was to add Martin® QC1™ Cleaner HD with a Martin® Twist™ Tensioner.

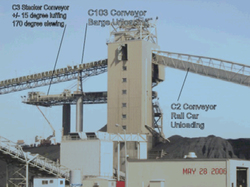

Read MoreConveyor Belt Inspection Identifies Carryback And Belt Wandering

The plant handles 1,000,000 tons of PRB coal per year and was experiencing carryback and belt wander on the rail unloading belt feeders. The carryback was reducing efficiency and profitability and increasing maintenance and cleanup expenses. Unsafe working conditions were a concern due to material accumulation on floors and walkways, creating slip/trip hazards along with fire hazards.

Read MoreMartin Products Help World's Highest Production Coal-Fired Power Plant

A coal-fired power plant produces over 300,000 tons per day. The plant was having trouble with dust and spillage at the conveyor transfer loading point in addition to excessive spillage and piles of fugitive materials under the conveyor belt. The problem led to manual cleaning and an increase in maintenance costs, resulting in regular and costly down-time and man-hours.

Read MoreMulti Port Air Cannon Eliminates Material Flow Problem

A cement plant in Turkey produced 9,500 tons of clinker per day. The rotary kiln entrance ramp area at the bottom of the preheater tower developed material flow problems because of the vertical angle of movement at the transition point and the horizontal angle of movement of the material.

Read MoreAir Cannons Immediately Increase Production

An existing lime kiln had been upgraded in 2014 with the addition of a pre-heater element to allow the plant to burn waste-derived fuels to save on energy costs. The introduction of the pre-heater section with its push rod type design started to create build up issues. Production was now critical with many kiln stops for manual cleaning and rodding.

Read MoreCoal-Fired Power Plant Needed Solution To Conveyor Belt Mistracking

A coal-fired power station was running into problems during the reclaiming and stacking out coal phase. The reclaim belt was consistently encountering tracking problems in both directions. Belt mistracking leads to material spillage, higher likelihood of worker injury, and increased maintenance expenses.

Read MoreConveyor Guards Drastically Reduce Risk Of Injury

The mine handles over 300 tons of crushed taconite per hour. Ore was continuously falling off of the belt, creating a safety hazard and putting workers in danger. The material spillage created the need for cleanup which is a dangerous maintenance task to perform since most conveyor accidents happen while performing maintenance and lubricating or checking the conveyor.

Read MoreSand Plant Experiences Spillage And Carryback Before Martin Steps In

Handling an abundance of sand every year, the plant had little time or resources to spend on inefficiency. Due to the lack of proper belt cleaning, spillage and carryback were present throughout the entire plant, leading to immense material loss. MSHA mandated corrective action be taken towards containment and collection to cut the amount of dust in half.

Read MoreDust Bags Filtrate Bark Dust At Paper Plant

A paper plant handles 20,000 tons of bark every month and was encountering huge dust problems at the head pulley of the conveyor near the boiler, creating the need for manual clean up. OSHA considered this area a combustible dust explosion risk, so the customer asked Martin to help them control the dust.

Read MoreAir Cannons Release Swarf From Silos

Following the machining of various items such as taps and other parts, the swarf produced is stored in a number of silos. Once these silos are full, the swarf is unloaded onto trucks. The problem occurred when this swarf, being mixed with cutting fluid, could not be dislodged from the silo making it nearly impossible to unload.

Read MorePower Plant No Longer Banging On Silos To Keep Coal Flowing

The plant has had a problem with blockage in the coal silo since it started operation and has manually solved the problem by hammering the silo walls. In some cases the blockage was very serious and completely stopped the flow of material inside the silo discharge. The plant has been running at reduced efficiency and has had to stop production to remove the blockage manually.

Read MoreAir Cannons Put An End To Manual Clean Out

The plant handles ash and was experiencing material buildup on the sides of the hoppers. This created a safety concern for those employees who had to perform manual cleanup. Employee safety is important to management so they reached out to Martin Engineering to help eliminate buildup and the need for manual clean out.

Read MoreSonic Horns Remove Buildup From SCR Catalyst Screens

A coal-fired power plant handles over a million tons of coal every year. The SCR catalyst screens had major build-up on them, decreasing productivity and efficiency. The existing sonic horns were not working properly and not improving the flow of material.

Read MoreTransfer Point Solutions Solve Fugitive Cargo Issues

A cement plant was experiencing increased costs due to fugitive cargo and dust piling around the plant’s petroleum coke conveyor transfer point. The material blocked access, degraded conveyor components and required expensive maintenance. Outsourced labor using rented equipment needed weekly downtime to clean the area, further raising the cost of operation and lowering production.

Read MoreTruck Vibrator Increases Worker Safety

Manlius Township was finding that truck drivers carrying road salt for melting winter snow and ice were having difficulty getting the entire load to empty out of the truck bed. This not only delayed the drivers in effectively spreading the material to improve road safety, but it also encouraged drivers to engage in potential unsafe activities, such as climbing into the truck bed to shovel out the remaining material.

Read MoreBelt Alignment Products Prevent Excessive Wear And Extend Belt Life

Minera del Norte´s Cemesa iron ore mining unit was having serious tracking problems with the conveyor belt leading from the primary crushing area. After drifting into constant contact with the frame, longitudinal tears formed on the belt, which reduced the usable width from 36 inches (914 mm) to 32 inches (812 mm). This caused spillage and lowered the production volume.

Read MoreAir Cannons Prevent Buildup on Kiln Walls

A mine was experiencing build up on the kiln walls, requiring continuous manual cleanup. This presented potential safety hazards for workers and increased man hours and overall expenses. Martin Engineering recommended installing Martin® 150-Liter Hurricane Air Cannons with retractable nozzles as well as Martin® Thermo Safety Shield.

Read MoreMartin Program Offers Hispanic Workers Advanced Training

With a diverse and multilingual company culture, the Hanson Aggregate Servtex Plant located in New Braunfels, TX was having problems finding advanced training for its Spanish-speaking staff. Most of the courses given by outside specialists with a deep understanding of the plant’s processes were conducted in English.

Read MoreConveyor Guards Improve Worker Safety

A plant had safety guards installed around the tail pulleys on some of its conveyors, fabricated with a heavy structural plate attached to the base of the conveyor frame. The main problem was their excessive weight and the difficulties encountered when they needed to be removed. This extended the time needed to service the pulleys and created a greater risk of injury or accident.

Read MoreXHV Air Cannons Unplug Wet Bark At Paper Manufacturer

One of the largest specialty paper manufacturers in North America, handling 300 tons of wet bark per hour, began experiencing a plugged chute. This blockage not only decreased productivity, but also created safety concerns. Manually unplugging the chute took an estimated two hours per day, adding to maintenance expenses as well as putting workers in danger.

Read MoreConveyor Belt Support Products Eliminate Spillage And Increase Productivity

Handling tons of PRB coal, a plant was having problems with dust and spillage at their conveyor transfer points. This material loss was costing the plant money in the form of decreased productivity, potential regulatory agency fines, and the cost of man hours to clean it up.

Read MoreAir Cannons Knock Down Sticky Coal From Hopper Walls

A power plant was having trouble with coal conditions. The material was wet and slightly sticky, which made it stick to the walls of the hopper, so much so that the material would accumulate and create a blockage in the hopper. Production couldn’t run smoothly, requiring temporary shutdowns so employees could manually knock down the material from the walls of the hopper.

Read MoreIndustrial Vibrators And Air Cannons Clear Blockage In Hopper

A steel plant was having trouble with iron ore sticking to the walls of the hopper. The wet and slightly sticky material would accumulate in the hopper creating a blockage. Production couldn’t run smoothly and the plant had to hire people to continuously knock material off the wall of hopper to keep the flow of material running smoothly.

Read MoreTransfer Point Solutions Correct Conveyor Belt Mistracking

Belt mistracking was leading to premature failure of the apron seal and therefore causing material to leak out. In an attempt to train the belt and prevent belt wander, the plant was constantly adjusting the conveyor belt at the tail pulley via the mechanical take-up. This was inefficient for the plant and the cost to replace prematurely-failing equipment was high.

Read MoreSonic Horns Eliminate Dry Particulate Buildup

A coal-fired power plant handles 5,000 tons of fly ash per month. The buildup of ash was causing velocity increases of the flue gas through both inlet ducts to the precipitator. This was causing opacity spikes in emission, increasing the risk that the plant would face large regulatory fines from the EPA.

Read MoreAir Cannons Drastically Reduce Unscheduled Outages At Cement Plant

A plant produces over a million tons of cement every year. Due to the large production volumes, material was building up on the raw feed material inlet chute to the feedshelf in the preheat tower. The plant was incurring unscheduled outages due to buildup and blockages, costing tens of thousands of dollars per year.

Read MoreTransfer Point Solutions Result In Safer, More Productive Coal Mining

A coal mining facility in China was experiencing dust and spillage from one of its conveyors. Fugitive dust lowered the air quality, clogged equipment and had the potential to affect workers’ health. Misalignment of the belt caused piles of lost product that had to be cleaned up, reducing system efficiency and wasting labor hours.

Read MoreTracker™ Installation Corrects Spillage and Fugitive Material

India’s leading integrated steel producer was having a belt tracking problem at its sintering plant located in the southern part of the country. With a capacity of 14.3 million tons per annum (MTPA) of bulk material, the main conveyor belt was becoming misaligned, causing excessive spillage and piles of fugitive material.

Read MoreBelt Cleaners Save Client $100K Per Year

The Springerville Generating Station handles 7 million tons of sub-bituminous coal per year. The coal yard was having problems with dust control, carryback and increasing wash down costs which negatively impacted the plant's production. Plant personnel were able to save more than $100,000 per year through the solution generated by the Martin team.

Read MoreNew VPlow Prevents Conveyor Belt Damage

Luminant Sandow handles 31,200 tons of lignite per month. The plant had an existing v-plow installed, at one point, which allowed the nose of the plow to dip down from wear or belt slack. When the nose would dip, the plow would dig into the belt, causing belt damage and even ripping of the belt. This problem cost the plant $26,000 plus labor.

Read MoreBelt Cleaners Reduce Downtime And Improve Safety

A petroleum coke refinery was experiencing spillage from materials adhering to the belt in the return. The operating staff had to manually clean the area and return the material back into the belt, creating unnecessary risk to workers and slowing down production, which increased operating costs.

Read MoreEasy-Access Air Cannons Increase Productivity

A large cement plant in Texas producing 900,000 tons of cement per year realized they had a problem with the air cannons on the feed shelf leading to the clinker. There was no access to the air cannons and they were in need of constant repair. To reach them, employees had to place scaffolding around the clinker.

Read MoreMartin® Tracker™ Corrects Conveyor Belt Misalignment At Steel Complex

An integrated steel complex producing flat steel (steel slabs) and long steel for both domestic use and export was having a problem with belt misalignment on one of the main conveyors, causing spillage of coal along the sides of the belt. As a result, the conveyor had to be shut down regularly so employees could manually clean the area.

Read MoreDust Surfactant System Helps Open-Pit Copper Mine with Excessive Dust

An open-pit copper and molybdenum mining complex outside of Phoenix, Arizona was experiencing excessive dust off the stockpile and it was exceeding the permitted levels.

Read MoreSurfactant Dust System Improves Employee Safety At Copper Mine

An open-pit mining complex was experiencing excessive dust problems. Previously, a drop chute was installed along a conveyor belt between the Crushing Plant and the Mill Plant. Dust was rolling off the conveyor belt causing both an exposure to employees’ health and a tripping hazard along the walkway adjacent to the belt.

Read MoreTransfer Point Solutions Reduce Airborne Dust At Rock Quarry

A quarry in Cedar Rapids was having trouble with fugitive dust. The Health Department was notified of severe dust being blown across the highway into a residential neighborhood. The Health Department set up a dust trailer to measure the dust particles near the residential neighborhood and findings revealed the dust exceeded code requirements.

Read MoreBelt Cleaners Save Copper Mine $22,000 Per Week In Downtime

An Arizona copper mine was experiencing excessive spillage from their conveyor belts feeding materials to the crushing facility. The carryback was so excessive they had to clean the area once per shift. Martin recommended a new cleaning system. The customer is now saving $22,000 per week and the cleaning requirements have changed drastically.

Read MoreAir Cannons Eliminate Blockages Caused By Sticky Iron Ore

At the largest cement producer in Texas, when iron ore would come in wet, or it would rain, the ore got very sticky and would stick to the inside of the silo. TXI would shut down for regular 24 hour periods so they could manually air lance the resulting blockage that was causing low feed rates. Working with Martin Engineering, they developed a plan to install a series of air cannons.

Read MoreSonic Horn Eliminates Downtime From Ash Accumulation

Ash accumulation issues had been forcing Alaskan Brewery Company to shut down its equipment to cool and manually clean the swirlers and collectors of its ash handler on a weekly basis. The process required an outage of 3-4 days, including as much as twelve hours of maintenance time with bottle brushes and bead blasting.

Read MoreSilo Cleaning Salvages 40 Tons of Cementitious Material

Over time, material dust in the three pneumatically-loaded silos began building up, first on walls and ridges and eventually clinging to all the interior surfaces. The severity of the problem became apparent to system operators when they noticed the walls of the silos actually starting to bulge outward. The need for repairs was clear and immediate, but the material build-up presented a serious obstacle.

Read MoreInstalling Dust Containment Solutions at Sugar Processing Plant

A sugar processing plant in California handles approximately 10,000,000 tons of raw sugar per year through their plant. One of the transfer points was giving them trouble with spillage. They contacted Martin distributor Applied Conveyor Technology (ACT) for their recommendation. ACT recommended upgrading the transfer point with cradles, wearliner, dust curtain and skirting.

Read MoreWashbox™ Cleaner Eliminates Dust and Carryback on Long Overland Conveyor

A metal mine in the Western US with long overland conveyors was having trouble with dust and carryback. The mine had to work with a high altitude location which resulted in cold weather and low humidity, long conveyor length, sticky material capable of hardening like concrete, and limited water. It was determined that the overall operation would be better served with a system that washed the belt.

Read MoreAir Cannons Eliminate Production Bottlenecks at Steel Production Plant

Rainy weather was causing buildup problems at a steel production plant. The material was accumulating on the walls of the hoppers causing a consistent production bottleneck. To knock down the buildup, the plant resorted to hitting the walls with tools. The frequency of the production stoppages were proving to be too costly - with high labor expenses, shortened refractory life and reduced hopper efficiency.

Read MoreMartin® Impact Cradles Boost Steel Production From 15% to 100%

As production increased at a steel production facility in Mexico, the existing impact cradles started to fail. After inspection, Martin® Impact Cradles were recommended due to the extreme operation conditions. Martin® Impact Cradles had been installed in the client's other mines so they were familiar with the product and knew these impact cradles would solve the problem.

Read MoreBelt Cleaners Improve Safety and Efficiency At Cement Plant

A cement plant was having trouble conveying gravel, gypsum, slag and other materials on the main conveyors feeding the clinker. Previously, they used less expensive brush-type cleaners, which were ineffective. They had to stop once a day for manual cleaning, and there was significant spillage, creating dust and security risks.

Read MoreTruck Vibrator Prevents Clogging In Turf Sweeper Screens

GreensGroomer had problems with one of their turf sweepers returning material back onto the turf. With powerful, dual Cougar® DC Truck Vibrators in the collection baskets, any infill material that is collected is quickly returned to the field making the removal of unwanted debris from synthetic turf, easier and more efficient.

Read MoreAir Cannons Stop Material Buildup with No Unscheduled Shutdowns

The Büyükçekmece cement plant located west of Istanbul, Turkey had to manually dislodge material buildup in one of their cyclones in order to maintain throughput. The unscheduled shutdowns to allow cleanout of the cyclone of the cone and deep tube interfered with production schedules and exposed maintenance staff to potential hazards.

Read MoreCement Plant Gets Extensive Conveyor System Overhaul

Like most cement manufacturing sites, GCC Dakotah employs an extensive conveyor system to handle raw materials and move finished product. GCC determined that significant upgrades could be made on conveyor transfer points to reduce spillage and dust emissions in the South Dakota facility. The upgrade included six transfer points on four conveyors.

Read MoreBelt Support Products Prevent Coal Accumulation

A coal plant produces a wet coal slurry that is pressed into fuel cakes, which drop down a 5 meter chute. With belt speeds of around 3.6 meters per second, the operation processes approx. 1.6 million tons per month. The large volume of material and relatively high speed had a tendency to release small amounts of spillage, which collected into significant accumulations.

Read MoreMartin® Hurricane Air Cannons Correct Ratholing In Chute

Soon after the plant went online, and the high-volume ramped up, engineers started noticing bottlenecks. They noticed a slowdown due to a material build-up in the chute feeding the export silo and discard bin. Operators determined that the freshly-pressed cakes were sticking to the walls of the chute, narrowing the space for product transfer and leaving “rat holes” which restricted flow.

Read MoreConveyor Belt Cleaner Resolves Carryback In Aggregate Application

A limestone company had a significant amount of material being carried back along the underside of the conveyors. This carryback would accumulate and create mounds of spillage that would pile up in excess amounts causing operational issues. For safety reasons and to increase production, the crew was required to shovel and wash carryback spillage daily.

Read MoreFiltrating Dust At Environmentally-Conscious Coal-Fired Power Plant

Orlando Utilities Commission – Stanton Energy Center (SEC) wanted to increase safety by limiting dust and spillage from one of its principal conveyors. Engineers wanted to reduce airborne particles, eliminate a potential source of trips and falls, and reduce clean-up and maintenance time, allowing critical manpower to be utilized elsewhere.

Read MoreMulti Port Air Cannon Saves Client Hundreds Of Thousands Per Year

Over time, operations personnel noticed a drop in SCR performance, and during a scheduled plant outage they inspected the system and discovered that fly ash contained in the exhaust stream was accumulating in the top layer. To address the situation, the plant was forced to enlist a contractor to come on-site 2-3 times each year during scheduled plant outages and evacuate the build-up.

Read MoreBelt Cleaner And Washbox™ Reduce Carryback By 99%

An innovative Michigan power supplier wanted to reduce surface dust and airborne particles, and reduce cleanup time at its PRB coal operation. Coal at the facility is fed either by rail, with a dumper that inverts the car and empties it directly onto a feeder conveyor, or with front loaders working off stockpiles in the yard. Both methods have the potential to generate dust.

Read MoreExisting System Jeopardizes Output Capacity And Employee Safety

Izmir Cimentas manufactures 5,550 tons per day of clinker from two production lines. They had an under-performing existing system, which was jeopardizing the plant’s output capacity by failing to remove accumulated material from the preheaters. The build-up issue needed manual removal on a daily basis, which required at least two hours’ maintenance each time.

Read MoreFlow Aid Solutions Result In Healthier Bottom Line

Votorantim Cimentos is one of the world’s leading manufacturers of cement, concrete and aggregates building two new plants as part of a massive $2 billion investment to enhance production throughout Brazil. These new plants are expected to produce approximately 8,500 tons of clinker per day between them. Starting in the early design stages of the project, Votorantim has maintained an intense focus on efficient material flow.

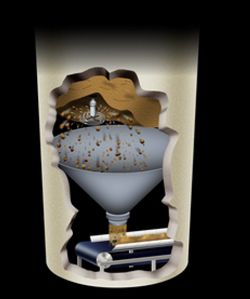

Read MoreMartinPLUS® Silo Cleaning Service Clears Cement From Storage Vessel

The Eagle Materials Illinois Cement facility experienced severe blockage of Type I cement in its 80,000 ton capacity storage silo when a support cable on the reclaim screw conveyor came loose, sending thousands of pounds of material down into the silo at one time. Like most cement manufacturers, the plant uses large storage vessels to hold finished material until its ready for shipment.

Read MoreDust Filtration And Dust Suppression Systems Mitigate Dust From PRB Coal

Constructed over 50 years ago, a five-unit coal-fired power plant in Omaha, NE was initially designed to burn Midwestern produced high sulfur coal. Though now cleaner, during the initial conversion process, the plant was not fully optimized to address the particular dust mitigation techniques necessary when handling PRB coal.

Read MoreMartinPLUS® Service Techs Replace Worn Out Chutes And Skirtboard Liners

Over time, operators began to notice increased dust and spillage around transfer points on four of its 42-inch conveyors. The problem was traced to worn chutes and skirtboard liners. A worn-out skirtboard liner plate was found to be exacerbating the problem. Rather than patching the existing chutes and liners, JEC want to see if they could find a better design solution.

Read MoreMartin® Air Cannons Optimize Material Flow

A cement facility includes a state-of-the-art, six-stage precalciner/preheater with a rated capacity of 660,000 tons of clinker per year. Efficient material flow is a key component of Drake's dry-process manufacturing, and accumulation in storage bins, process vessels or feed pipes could choke even this well designed system. The facility's system required some fine tuning.

Read MoreNew Transfer Chute Improves Material Handling Operations

The Vancouver Wharves terminal in North Vancouver, BC delivers inbound and outbound services to shippers moving cargo between all regions of western Canada, handling mineral concentrates, liquids (diesel and jet fuel), sulfur and specialty agricultural products. The terminal handles more than 600,000 metric tons of mineral concentrate per year across five different storage buildings.

Read MoreCopper Mine Solicits Martin's Expertise For Conveyor Belt Improvements

A copper mine in Arizona is a mine-for-leach operation and produces copper cathodes. The operation consists of two open pits feeding a crushing facility with a capacity of 103,000 metric tons-per-day. The crushed ore is delivered to a single leach pad by a series of overland and portable conveyors. The client hired Martin Engineering to evaluate their current system.

Read MoreCougar® Pnuematic Piston Vibrator Eliminates Production Bottleneck

At a power plant in Vernal, Utah, coal was hanging up on the hoppers beneath the storage silos. Buildup on the walls of the hopper was an ongoing headache for operating personnel and a consistent production bottleneck. The plant resorted to climbing ladders and scaffolding and using sledge hammers to knock the coal loose.

Read MoreMartin® Hurricane Air Cannons Alleviate Ash Buildup

Koda Energy was battling significant buildup problems. Efficient material flow is a critical element of biomass-fired boilers, and accumulation or blockages can take a big bite out of a plant’s efficiency. Ash buildup on furnace walls and tubes can choke the process, degrading equipment performance and introducing the potential for safety risks during clean out.

Read MoreInnovative Utility Uses Conveyor Guards As Proactive Safety Measure

An innovative electric utility with an 80+ year history of delivering low-cost, reliable power wanted to implement measures to make its plant safer and take steps to ensure greater OSHA compliance by installing safety guards around its high-speed conveyor system. The solution needed to be in line with the company’s reputation as one of the most safety-conscious electricity providers in the nation.

Read MoreMartin® Multi Port Air Cannon Increase Productivity In Cement Plant

A cement plant was battling buildup problems in the cyclone discharge pipe following meal pipe expulsion. The buildup of sticky material created blockages leading to a smaller output opening at the bottom of the cyclone discharge pipe, causing serious production loss. To prevent blockages in the Cyclone discharge pipe, Martin Engineering determined suitable places for air nozzles, and installed two Martin® Multi Port Air Cannons.

Read MoreMartin® ApronSeal™ Skirting Contains Dust And Spillage

A copper mine in Arizona was dealing with existing skirting that was not containing dust and spillage. This fugitive material led to the need for manual cleaning/shoveling of the walkway every day. The plant even bought a temporary conveyor to help alleviate this issue. Martin installed new heavy duty Martin® ApronSeal™ Skirting on the problematic conveyor.

Read MoreMartin® Belt Cleaners Solve Spillage Issue In Copper Mine

Spillage and carryback were accumulating at the tail section of one conveyor. This area could not be cleaned without shutting down the associated ball mill (which grinds copper ore) and locking out the conveyor. Martin installed two belt cleaners. There wasn't enough room to modify the dribble chute to accommodate any secondary cleaners so two cleaners were squeezed into a very small area.

Read MoreTruck Vibrator Offers More Complete Emptying Of Dump Trucks

Humphries Haulage was experiencing incomplete emptying of their dump trucks. Even fairly dry materials can be affected by weather and other conditions, making them extremely difficult to evacuate completely. A short vibration cycle can be a very effective way to break the surface tension and allow the load to slide out.

Read MoreIndustrial Waste Truck Manufacturer Increases Productivity With Truck Vibrators

Manufacturer of industrial vacuum loaders, hydroexcavators and sewer cleaners needs solution for Off-loading of industrial waste from these vehicles. It can be a difficult task as stubborn materials don't always completely empty from the load. Vactor Manufacturing uses four different models of Cougar® truck vibrators to assist in the off-loading of industrial waste.

Read MoreBelt Cleaner Minimizes Need For Difficult Manual Cleaning

This cement plant produces one million tons per year. The plant uses a total of nine weigh feeders to move the raw materials—limestone, sand, shale and iron ore—from hoppers to the belt that conveys the material to the roller mill to be ground for kiln feed. To contain the cargo, these feeders use corrugated sidewall belts. Given their wall height, these belts are difficult to clean.

Read MoreMartinPLUS® Silo Cleaning Corrects Ratholing In Cement Vessel

A cement plant was experiencing build up which was hardening on the storage vessel’s walls. This produced a hardened rat hole that slowed flow and reduced live storage capacity. A leaky roof had contributed to the problems. It was estimated that the damp cement buildup reached 20 tons of material in the bin.

Read MoreMartin® Washbox™ Offers Unique Solution To Carryback Problem

Crushed molybdenum ore is transported to the processing plant on overland belt conveyors. As the conveyor passes through a preserve, the operation was concerned about the escape of carryback. To provide effective belt cleaning in the challenges of the operation’s high altitude and cold climate conditions, Martin Engineering developed a special belt washing station.

Read MoreDeteriorating Power Plant Needed Material Handling System Redesign

The coal conveying system at the power plant needed refurbishment. Problems included fugitive material arising as dust and spillage, as well as a general deterioration of the condition and performance of the system. Complicating the project was the plant’s need to remain in operation during the work. The plant would need to run the coal handling system almost every day.

Read MoreMartin® Railcar Opener Ensures Smooth Unloading

Up to four times a week, the terminal receives unit trains of 40 railcars at a time. Unloading proceeds round the clock, one car every 40 minutes, until all cars are emptied allowing the train to return to the manufacturing plant for another load. To keep the trains in motion, and the terminal’s five silos full, it is important that unloading proceed smoothly.

Read MoreMartin® Tracker™ Corrects Conveyor Belt Mistracking

Canada Steamship Lines Inc. owns and operates the largest fleet of self-unloading vessels in the world. One of these vessels is the CSL Assiniboine, which plies the Great Lakes carrying cargos of up to 33,860 tons of coal, grain or taconite pellets. The ship’s self-unloading system consists of three conveyors belts below the vessel’s holds.

Read MoreTransportation Company Needs More Flexible, High Discharge System

To maintain leadership in self-unloading technology, CSL had set ambitious goals for the discharge systems of new ships, including simplicity, maintainability, increased load capacity, flexibility, high discharge rates and environmentally-friendly operation. In March 2001, the CSL Spirit joined sister ships Sheila Ann and Sophie Oldendorff as the newest additions to the CSL International fleet.

Read MoreMartin Vibration Products Replace Inadequate Competitor Vibrators

At a cement company in California, air powered vibrators used to boost material flow from the unloading railcars produced high noise levels. In addition, the heavy weight of these vibrators prompted concerns about injury to the operators who installed units on railcar outlets multiple times each day. Martin Engineering was asked to provide a solution.

Read MoreCoal Spillage Significantly Reduced By Martin® Transfer Chutes

All coal burned at the plant moves through a single chute. The path is at an angle of roughly 90 degrees from either of the discharging conveyors, making for a difficult transfer. A drop height of 30 feet also creates problems, including a large flow of induced air, resulting in dust escape, high levels of impact leading to idler damage and belt abrasion from poor control of the flow of coal.

Read MorePlugged Chutes Fixed By Martin® Inertial Flow™ Transfer

Superior Midwest Energy had little opportunity for maintenance and equipment changes due to its continuous loading schedule. The plant was running into constant plugged chutes, leading to spillage and a lot of man-hours spent on cleanup. Martin Engineering designed custom-engineered chutes specifically to suit the needs of Superior Midwest Energy.

Read MoreAir Cannons Reduce Need For Manual Cleaning

A cement plant produces 1,100,000 metric tons per year of clinker from one line. However, air cannon systems supplied by competitors were not working properly, leaving material buildups in the preheater tower. The buildups required manual cleaning at least two hours every shift, and a monthly slowdown for a major cleaning.

Read MoreDust Curtain Keeps Fugitive Material From Nearby Homes And Businesses

A Minnesota power generating facility was having trouble controlling dust and spillage and preventing fugitive material from reaching nearby homes and businesses. With variable size and moisture content of the fuel, chips would fall back down. Reducing material turbulence during transfer is essential to prevent fugitive dust.

Read MoreTransportation Company Needed Solution To Coal Dust

Aurora Energy Services needed to increase the flow of coal through the shiploader at its Port of Seward terminal. But transfer chutes on the shiploader choked at rates above 750 mtph, which limited loading speed and slowed ship-turnaround. Even worse, the escape of coal dust during loading led to concerns from a nearby cruise ship dock and marinas, as well as environmental groups.

Read MoreExternal Wear Liner Stops Spillage On Belt Feeders

At a generating plant, 5000 tons per day of PRB coal are metered via belt feeder onto conveyors and into the plant's ten bunkers. With surge of material as railcars unload, combined with the high head pressure from the hoppers, the belt feeders suffered extensive spillage. This spillage was compounded by the worn-out condition of the chutes.

Read MoreMartinPLUS® Maintenance Services Improve Mining Operation

Located in Indonesia is a high volume operation producing gold and copper. To handle the vast quantities of ore, the mine uses large, fast, high capacity conveyors. Belts are typically 72 or 84 inches in width, and operate at 4 m/sec. To simplify supplier arrangements, PTFI sought one belt cleaner supplier who could provide both installation and service.

Read MoreAir Cannons Dramatically Improve Employee Safety

At this rail-to-barge trans-loading facility, a set of six stacker tubes connected by conveyors allows the stockpiling of coal. Coal would hang up inside the tubes, sticking to the walls, building up inside. To clean coal out of the tubes, the operation used manual labor. A man-lift would be used to raise personnel to the lowest window of a stacker tube, so they could dig out the accumulated coal.

Read MoreCoal-Fired Power Plant Experiences Dramatic Reductions In Dust And Spillage

Plant Daniel’s two 500 MW units burn 2.9 million tons of a blend of bituminous and PRB coal annually. The coal handling system had problems with dust and spillage. The plant wanted to reduce dust and spillage, and their related hazards, and at the same time control the expense for the contract labor used for clean up and wash down procedures.

Read MoreFlow Aid Solutions Reduce Production Outages At Cement Plant

A cement plant in Matozinhos, Brazil is one of Brazil’s leading cement production facilities. Opened in 1959, the plant produces 660,000 (600,000 metric tons) tons of clinker per year. The need to improve efficiency and maintain production without outages led company officials to consider ways to improve flow through the plant’s pre-heater tower.

Read MoreBelt Sealing Products Reduce Cleanup and Maintenance Costs

Located on the Ohio River, the Mt. Vernon Transfer Terminal moves approximately 1.8 million tons of coal annually from trucks or railcars to barges for shipment to power plants. Excessive spillage from an underground belt below the railcar dumper increased cleanup costs and maintenance headaches. This conveyor is 84 inches wide with an operating speed of 150 fpm.

Read MoreBelt Cleaner Improves Efficiency And Extends Blade Life

At a mine in Fayette County, West Virginia, coal-carrying conveyors both above and below ground need to be cleaned to reduce operating problems and safety issues. Cleaning these belts can be difficult as the multiple mechanical splices on many belts will reduce cleaning efficiency and shorten blade life.

Read MoreTransfer Point Solutions Increase Productivity At Container Board Plant

Bark and wood waste are used as fuel to produce heat and steam for this container board plant. A series of belt conveyors 36 to 48 inches wide carry bark to the powerhouse. The Pine Hill Mill began a program to improve its materials-handling operations and eliminate fugitive materials. The bark conveying system was the first system to be upgraded.

Read MoreImpact Cradles Minimize Conveyor Belt Damage

A drop of approximately 23 feet onto the belt proved hard on conveyor components, causing excessive wear and damage to both the belt and idlers. Martin® Impact Cradles absorb the impact originating in lumps of material landing on the belt. The cradles prevent impact damage to the belt and other conveyor components and stabilize the belt line to reduce load zone spillage.

Read MorePiston Vibrator Corrects Bottleneck And Decreases Shutdowns

The plant’s mixture of coal and shredded tires (TDF) hangs up on the feed hopper grizzley. The plant has removed several of the grizzley bars, creating a larger opening but material still hangs up. This bottleneck forces plant personnel to push the fuel mixture over the pit, and then get out of the loader to poke the pile through the grizzley with a shovel.

Read MoreMartinPLUS® Maintenance Helps Steel Plant Overcome Regulatory Issues

A steel plant’s material handling conveyors suffered problems with dust and spillage. This fugitive material led to problems with neighbors and regulatory agencies. To resolve complaints from the nearby city of Vitoria, CST entered into a long-term contract with Martin Engineering's subsidiary in Brazil for the maintenance of its conveyor system.

Read MoreMartin® Air Cannons Eliminate Dust From Refractory

This fuel-efficient kiln operates by alternating the firing of two shafts, so one shaft burns while the other acts as a fuel for exhaust gases. The heated gases leave the combustion chamber through arches opening into a crossover channel. Dust would adhere to the refractory in the arches, choking the flow of gases from one combustion chamber into the other.

Read MoreMartin® Self Adjusting Skirting Faster And Easier To Install

At cement company, abrasive clinker would rapidly wear out the skirtboard sealing strips, creating a severe spillage problem at the conveyor’s loading zone. The sealing system required replacement every three weeks. Martin Engineering provided “Personalized Performance” by tailoring the Martin® Self Adjusting Skirting to provide improved corrosion resistance while remaining within the customer’s budget.

Read MoreClient Tests Martin Belt Cleaners In Side-By-Side Comparison

At an agglomeration plant in Peru, plant management wished to compare the performance of competitive belt cleaning systems. The plant operates parallel (redundant) conveyor systems that carry approximately the same material load on the same operating schedule. Installing competing belt cleaners on the side-by-side conveyors allowed the plant to compare belt cleaning results.

Read MoreMartin Transfer Point Products Reduce Risk Of Fire Or Explosion

This power plant had dust and spillage escaping from the coal-handling systems. To boost material-handling efficiency and reduce the risk of fire or explosion, Martin installed taller and longer skirtboard walls, new belt support systems, abrasion-resistant wear liners, and a multi-layer, low-pressure sealing system on the outside of the chute walls.

Read MoreMartin Designs Special Suspension Bracket On Suspended Conveyors

The operation uses underground conveyors suspended by cables from the mine ceiling. Keeping the belts running in the center of the suspended conveyors is a continuous challenge. Martin designed a special suspension bracket to allow installation on the suspended conveyors. Units are built with bronze bearings to avoid problems with static electricity in the underground coal mine.

Read MoreMartin® Belt Cleaner Requires Less Maintenance and Lasts Longer

QCM moves an average of 8.5 million tons of iron pellets per year through its shiploading facility. The reclaim conveyor was creating so much carryback that the workers had to wash down the structures and pivot rail system between each shipload. This could be done without problems from April to December, but was impossible during the winter months.

Read MoreCement Company Benefits From Martin® Air Cannons

A cement plant in Florida was producing 2,500 tons per day of clinker. Air cannons were not included in the design of this new plant. Martin Engineering developed a plan for the installation of 45 Martin® Air Cannons on the new pre-heater. Crews from MartinPLUS® Services group installed the pre-heater air cannon system.

Read MoreMartin® Belt Cleaners Save Client Over $55,000 Per Year

An aluminum recycling plant was unhappy with the performance of a competitor’s belt cleaners, and thought replacement blades were too costly. As a result of poor cleaning performance, plant employees were required to vacuum fugitive material from the conveyor pits two to three times per week, at a cost of $1,500 to $2,500 per vacuuming.

Read MoreMartin® Air Cannons Maintain Boiler Feed Rate At Power Plant

A power plant uses petroleum coke - a refinery waste product - to fire its boilers. But the sticky material would build up on the walls of the chutes carrying it from the gravimetric feeders to the boiler. Instead of the 300 tph required, the feed rate would slow down to 75 to 100 tph, starving the boilers. The plant staff resorted to frequent cleaning of the chutes.

Read MoreFlow Aids Remove Sawdust At Particleboard Manufacturer

Before wood shavings can be pressed into particleboard, they are dried in a chips dryer. The plant uses a flat line, ten-zone oven. Screens form the sides of the oven to keep the chips away from the coils that heat the oven. Sawdust picked up by the oven’s circulating air would stick to the screens, clogging the openings and reducing air movement.

Read MoreMartin® Air Cannons Require Less Maintenance

To preserve the life of the air cannon’s piston and sealing o-rings, oil was added to the air supply. But as the air cannons would discharge the oil would collect on the filter, causing the filter to plug or bind. Filter efficiency would go down, which in turn reduced plant output and increased maintenance problems. The plant installed Martin® XHV Retrofit Valves on the air cannons.

Read MoreMartinPLUS® Installation Services Gets Rave Reviews From Happy Client

A power generating station needed to improve the performance of a vibratory feed chute. To improve the situation, MartinPLUS® Services installed an electric vibrator on the feeder pan. The crew also removed the existing UHMW lining and replaced the cables that suspend the vibrating pan. The new feeder and chutes work as projected.

Read MoreMartinPLUS® Service Technicians Conduct Power Plant Overhaul In Michigan

The drag chain conveyor under a slow moving feed conveyor was inoperable. Martin Engineering was called in to engineer the existing system’s tear-out and design a new dribble chute. MartinPLUS® Service Technicians prepared and sent detailed drawings with a step-by-step procedure for removal of the drag chain conveyor.

Read MoreTransfer Point Solutions Resolve Carryback At Kentucky Energy Plant

An energy company in Kentucky was having problems with carryback on their side-by-side transfer belts carrying coal from the central reclaim tunnel to the bunkers. They hired Martin Engineering to find a solution. Martin recommended a variety of belt support, belt sealing, tail protection and dust containment solutions as well as safety accessories.

Read MoreSequencing Air Cannons Clear Kiln

This plant is a new, state-of-the-art facility, but designed without air cannons on the pre-heater tower. Consequently, material flow through the pre-heater was subject to blockages, requiring excessive (and potentially risky) labor. Martin installed air cannons, set to fire in a sequence starting from the kiln feed shelf and working up, alternating side to side, until all the cannons have fired and then starts over.

Read MoreAir Cannons Stop 60,000 Pounds Of Sugar From Sticking To Vessel Walls

Fine sugar used in a line of powdered drink mixes would build up on the walls of the storage silo. This choked the flow of sugar out of the silo leading to slowdowns in production. By the time of the annual outage, there would be between 40,000 to 60,000 pounds of sugar stuck to the vessel walls. The cost to recover and reprocess this sugar was a considerable drain on the budget.

Read MorePower Plant Needs Cleaner, Safer, More Productive Material Handling System

The Warrick Power Plant is operated by the Alcoa Generating Company to supply electricity for smelting operations at Alcoa’s Warrick facility. The plant’s coal handling equipment needed reconstruction and improvement, including improved systems to control spillage and dust, to provide a cleaner, safer and more productive coal handling system.

Read MoreFlow Aids Return Plant To Designed Production Rate

Material would build up at the inlet to the pre-heater tower. These accumulations choked the flow of material, reducing the plant’s production from its design rate of 3,000 to 2,700 tons per day. To regain capacity, the plant would take unscheduled outages to allow manual cleaning of the ducts. After cleaning, the buildup would resume, with flow choked again within ten days.

Read MoreAir Cannons Move Sticky Coal From Bins

To keep up with the steel mill’s around the clock, seven days-per-week schedule, the railcar dump must provide 3,000 tons of coal per day, every day. But the operation was at the mercy of the handling properties of the coal. Coal with higher moisture content, material density or size ranges would hang up on the walls of the receiving bin below the car dumper.

Read MoreCoal-Fired Power Plant Applauds MartinPLUS® Services Installation Team

A coal-fired power plant in Iowa was ready to replace their ineffective belt cleaners and cumbersome air tensioning system. Plant officials agreed to test a Martin® QC1™ Cleaner XHD from Martin Engineering. The test installation provided a blade life of approximately one year, and its “one-pin” blade change simplified maintenance.

Read MoreMartinPLUS® Installation Services Redesign Power Plant Transfer Points

An energy company in Lansing, Iowa was facing severe spillage problems in underground loading points. The steel structure on part of conveyor feeding system was shot. It was old and worn out. There were bows and dips in the skirtboard, and it wouldn't stay sealed. This created excessive dust and spillage in the tunnel.

Read MoreSpillage Problems Corrected By Transfer Point Redesign

A coal-fired power plant was suffering from extensive spillage and other problems. The plant’s coal-conveying system needed an extensive upgrade, including new belt cleaning systems and improved transfer point systems.

Read MoreMartin® SHD Cleaner Now Considered Industry Standard In European Lignite Mines

A lignite mine must move over 350 million tons of overburden per year. The mining method is open cast excavation using bucket wheel excavators and high-capacity conveying systems. To control expenses, the client wanted to extend the life of belt cleaning components while reducing the maintenance these systems required.

Read MoreAir Cannons Eliminate Need For Water Blasting

A plant used water blasting to remove material buildups from the pre-heater tower’s riser duct. Personnel were required to open access doors into the tower twice a day to remove the accumulations with a high-pressure water spray. The water blasting caused production problems, dropping lumps into the kiln feed, downgrading kiln efficiency and clinker quality.

Read MoreSugar Processor Hires Martin Engineering For Systems Analysis

The 10 conveyors in the raw sugar conveying system suffered severe spillage and carryback as well as belt wander that originated in the accumulation of fugitive material on rolling components. Plant management made a commitment to solve these problems. Martin Engineering provided a detailed engineering study that listed a number of recommendations.

Read MoreBelt Support System Allows For 24/7 Operating Schedule

A major expansion at a gold mine included an innovative idler design developed by Martin Engineering in conveyor transfer areas. The mine’s high-capacity conveyor system faces continuous loads and heavy impact from 8-inch lumps of copper ore. To withstand this impact, Martin Engineering designed a special belt support system.

Read MoreCoal Conveying System Plagued By Dust, Spillage and Carryback

A power plant’s coal-handling system starts with a reclaim conveyor under the stockpile and makes its way to the coal gallery. There, twelve conveyors distribute the coal to six different bunkers that feed the plant’s three coal-fired boilers. The plant suffered general dust, spillage and carryback problems throughout the coal conveying system.

Read MoreMartin Creates Long-Term Solution To Material Flow Problems

During the power plant’s summer outage, an independent contractor designed and installed new chutes to feed the coal mills. But at start-up, material clogged in these new chutes and closed off the flow of coal into the boilers, causing the plant to shut down. The plant needed an emergency-response “quick fix” to return to production and a solution for long-term correction.

Read MoreMartinPLUS® Offers Process Improvement Recommendations in Coal-Fired Power Industry

In normal operations at a coal-fired power plant in Arkansas, a 72-inch (1800 mm) feeder belt loads coal onto another 72-inch (1800 mm) belt. Plant engineers wanted to be able to bypass the second conveyor and load material directly from the first conveyor to the last. The plant needed engineering assistance to accomplish this redesign and avoid bottlenecks and plugs in the new chute.

Read MoreMartin® Air Cannons Result In No More Unscheduled Outages

At CEMEX in Tennessee, buildup on the walls of the pre-heater was a continuing headache for operating personnel and a consistent production bottleneck. To knock down the buildup, the plant resorted to water blasting, but the frequent water blasting proved costly, with high labor expenses, shortened refractory life and reduced kiln efficiency.

Read MoreTransfer Point Products Improve Severe Spillage And Dust Problems

At a cement plant in Kentucky, the clinker transport system had severe problems with the escape of spillage and airborne dust in the loading zones of three conveyors. Martin® Transfer Point Solutions were recommended to stop the spillage and dust problems. To improve the clinker conveying, the plant agreed to upgrade the transfer points.

Read MoreInadequate Belt Cleaners Replaced With Martin® Products

At a cement plant in Iowa, a 42-inch (1067 mm) wide belt carries material to the stockpile from the quarry’s primary crusher. But poor performance by the conveyor’s homemade “slab” belt cleaner left piles of carryback under the conveyor, interfering with its ability to move to the stockpile, while shortening component life.

Read MorePlant Needed Solution To Coal Dust Fire Hazard

The transfer chutes of these redundant systems would choke, cutting coal flow to 550 tph, roughly half the system's design capacity. This required the operation of both twin bunker feed conveyors on longer schedules without allowing for system maintenance. In addition, the transfer points created large quantities of coal dust, creating a fire hazard and maintenance headache.

Read MoreMartin® Self Adjusting Skirting Maintains Effective Seal Without Maintenance

A salt plant in Ohio was looking to upgrade their skirtboard sealing systems. The existing slab rubber skirting was in bad repair and leaking material. With less than two inches (51 mm) of free belt area on each side of the loading zone, the conveyor had very limited amount of space available for installation of a sealing system.

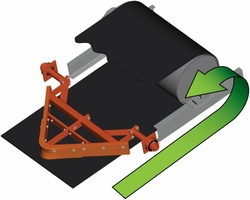

Read MorePSP 1329 - EVO® Belt Tracking

The belt was experiencing serious tracking issues, which caused damage to the belt and structural components, as well as spillage along the conveyor path.

Read MoreMr. Blade® Program utilizes Martin® Belt Cleaners and N2 Technology to Improve Safety and Efficiency at a Limestone Plant

Under performing belt cleaners were causing excessive safety and maintenance problems until our Mr. Blade technician arrived on the scene.

Read MoreMr. Blade® Program utilizes Martin® Belt Cleaners and N2 Technology to Improve Safety and Efficiency at a Limestone Plant

Under performing belt cleaners were causing excessive safety and maintenance problems until our Mr. Blade technician arrived on the scene.

Read MoreMr. Blade Technician Installs Durt Hawg Cleaner to Eliminate Carryback

Sand/aggregate operation struggled to obtain consistent belt cleaning on two stacker conveyors

Read MoreMr. Blade Program Delivers Solution to Carryback Problem

The new Mr. Blade program from Martin Engineering assures customers of professionally installed replacement blades that are matched to their specific operating conditions for optimum cleaning performance and service life. Image Materials benefits from a consistent supply of freshly-molded, high-quality blades delivered directly from the factory and installed by a trained service technician.

Read MoreMr. Blade Program Delivers Solution to Carryback Problem

The new Mr. Blade program from Martin Engineering assures customers of professionally installed replacement blades that are matched to their specific operating conditions for optimum cleaning performance and service life. Image Materials benefits from a consistent supply of freshly-molded, high-quality blades delivered directly from the factory and installed by a trained service technician.

Read MoreMartin® Typhoon Air Cannon

"Safety is critical, and we are very happy with this solution," said an operator. "The improvement to efficiency exceeded our expectations."

Read MoreMartin® Transfer Point Products

Martin service technicians visited the site and recommended a combination of passive dust management and fugitive material controls to alleviate the problems.

Read MoreMartin® Total Transfer Point Solution Reduces Dust and Spillage

A silver and lead mine in Northern Mexico was experiencing excessive downtime on a main conveyor transporting raw ore. Spillage and dust emissions were pervasive in the loading and discharge zones, while access for maintenance and cleanup was difficult and unsafe.

Read MoreMartin® SQC2S™ Secondary Cleaner STS™

After installation, operators noticed a drastic and immediate reduction in the amount of cargo clinging to and falling from the belt. Material no longer spilled onto walkways or fouled moving components.

Read MoreMartin® Silo Cleaning Service

Using the Martin® HD Whip™, the work took considerably less time than the previous manual method, justifying the cost of the service in the first cleaning. After observing the ease of the process, managers were convinced that this was the solution moving forward.

Read MoreMartin® PV Cleaner, Martin® Twist™ Tensioner

"Our maintenance crews have crucial functions they need to address to keep the plant running," said a representative. "Not having to worry about carryback and spillage is important."

Read MoreMartin® Impact Cradle MD

Nearly a year and a half after installation, operators report that there has been no damage to the belt and they are just now replacing some bars in the main impact zone. They report that downtime and labor due to maintenance on the loading zone has been drastically reduced, improving production and reducing the cost of operation.

Read MoreMartin® Belt Cleaners Reduce Carryback by 78%

A large fracking sand plant in Texas with 5MM TPY capacity was experiencing serious carryback issues on its main conveyor, with wet sand clinging to the belt. The material would either transfer to the bend pulley, fall to the ground or fall into the take-up pulley where it would damage the belt. Cleanup was needed almost every day, at times becoming so bad that the process would have to be shut down for maintenance.